Mumbai-Ahmedabad Bullet Train Project: Breaking down engineering secrets of India’s first high-speed rail corridor – Railways News

A lot has been said and written about India’s first bullet train from Mumbai to Ahmedabad – its ambitious goals and grand promises. But beyond the headlines and soundbites lies the truth of extraordinary technology that many of us are yet to understand. This article aims to peel back the layers of media hype and offer a fresh, insightful look into the true marvel of engineering behind this high-speed revolution. Picture a train gliding effortlessly, slicing through the landscape at mind-boggling speed. How does it work? What makes it tick? Here, we’ll uncover the innovation driving India’s leap into the future of rail travel, and see why this project is more than just a high-speed promise—it’s a technological game-changer.

Mumbai-Ahmedabad Bullet Train Alignment

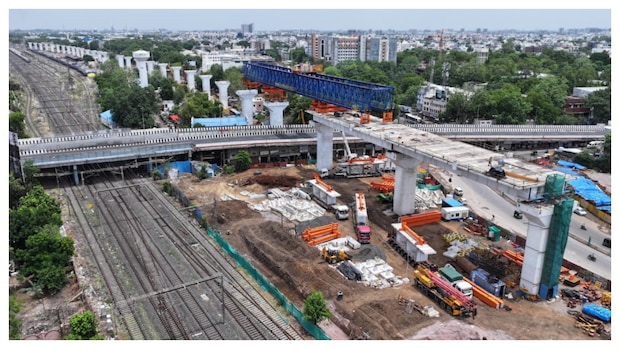

The National High Speed Rail Corporation Limited (NHSRCL) spokesperson tells Financial Express that the Bullet Train corridor features approximately 90% of its route elevated, strategically designed to minimize disruptions to the existing infrastructure. This elevation approach enhances both efficiency and safety throughout the project.

Full Span Launching Method: A revolutionary construction technique introduced for the first time in India

The Full Span Launching Method is approximately 10 times faster compared to the traditional Segmental Construction technique. The process involves casting girders in a dedicated yard and then transporting them to their designated positions using specialized equipment. This advanced method significantly accelerates the construction timeline and ensures higher precision in girder placement. The use of FSLM in India is notable as it is being adopted for the first time in the country, positioning India among a select group of nations that have mastered this technique. Let’s breakdown the construction process for you.

Ukrainian air defence neutralises over 10 drones in Kyiv amid renewed assault

Brazil-India Relations: A New Era of Strategic Cooperation

Denial of jail meeting with Arvind Kejriwal ‘Arbitrary, illegal and completely unjustified’: Sandeep Pathak tells HC

Internet services suspended in Udaipur after communal tensions flare over school student’s stabbing

Work in progress at Vadodara district – July 2024 (Image: NHSRCL)

Work in progress at Vadodara district – July 2024 (Image: NHSRCL)

At the heart of this innovation are the 40-meter-long Full Span Box Girders, each weighing an impressive 970 metric tonnes. These giants are crafted from 390 cubic meters of concrete and 42 metric tonnes of steel, all cast in a single piece without any construction joints. This makes them the heaviest Pre-Stressed Concrete (PSC) Box Girders ever used in India’s construction history. By employing this technique, the Mumbai-Ahmedabad High-Speed Rail corridor project is not just moving swiftly but also setting new benchmarks in the industry.

Precision and Efficiency in Action for India’s First Bullet Train

The construction process for these colossal girders is a marvel of modern engineering:

Casting and Transport: Girders are first cast in dedicated yards and then transported using a Straddle Carrier. They are carefully moved to a predetermined location where a Bridge Gantry lifts them onto a Girder Transporter. This transporter then navigates the girders to the launching site.

Launching: At the launch site, a specially designed launching gantry takes over. It meticulously positions the girders with pinpoint accuracy. This entire process demands exceptional precision and expertise, reflecting the high level of technical skill involved.

Completion of ADIT Tunnel in Navi Mumbai for Bullet Train Project – July 2024 (Image: NHSRCL)

Completion of ADIT Tunnel in Navi Mumbai for Bullet Train Project – July 2024 (Image: NHSRCL)

Building Speed and Efficiency for High-Speed Rail Corridor

To keep the project on track, construction is conducted in parallel on both the substructure and superstructure:

Substructure Work: This includes the installation of piles, pile caps, piers, and pier caps.

Superstructure Development: Casting yards have been strategically developed along the alignment to produce both Full Span and Segmental Girders. These yards are equipped with advanced facilities such as jigs for rebar cages, hydraulically operated casting beds, batching plants, aggregate stacking areas, cement silos, and labor camps to ensure high-quality and efficient casting.

Superstructure work in progress at GAD 1967, Anand district – July 2024 (Image: NHSRCL)

Superstructure work in progress at GAD 1967, Anand district – July 2024 (Image: NHSRCL)

Mumbai-Ahmedabad Bullet Train’s Current Progress and Achievements

As of 31st July, the project has successfully completed 200 kilometers of viaduct construction. The NHSRCL has successfully cast 231 km girders, out of which 200 kilometers is already launched.

So to reiterate what we promised you in the beginning, the Bullet Train embodies a leap in technology and precision, showcasing methods and innovations that redefine the possibilities of modern construction. With its 90% elevated alignment and pioneering Full Span Launching Method, the project is not only setting new standards but also heralding a new era in rail travel. This ambitious venture promises to transform connectivity, driving India into a future where speed and efficiency reshape the landscape of transportation.

Images are for reference only.Images and contents gathered automatic from google or 3rd party sources.All rights on the images and contents are with their original owners.

Comments are closed.